- Excellent chemical resistance: Withstand aggressive etchants and cleaning chemicals

- Low surface energy & non-stick properties: Reduce particle adhesion, improving yield

- High purity: Minimal leaching or contamination

- Electrical insulation: Critical for equipment safety and performance

- Durability in vacuum, plasma, and high-temperature environments

1. Wet Process Equipment

-

Tanks, ducts, pipes, valves, and fittings are coated with PFA, PTFE, ETFE, or ECTFE

-

Protects against acids used in wafer cleaning and etching

2. Plasma Etching & CVD Tools

-

Chambers, electrostatic chucks, and fixtures are lined or coated with fluoropolymers

-

Prevents corrosion from plasma gases (e.g., CF₄, SF₆, Cl₂)

3. Wafer Handling & Transport

-

Fluoropolymer coatings prevent particle contamination on wafer carriers and chucks

4. Cleanroom Components

-

Coatings on rollers, trays, and ducts minimize contamination and chemical attack

5. Analytical & Process Control Instruments

-

Protects sensors, flow meters, and probes exposed to corrosive gases and liquids

- Longer equipment life → reduced downtime and maintenance costs

- Improved wafer yield → fewer defects due to contamination or corrosion

- Cost savings → fewer replacements, better uptime

- Compliance with cleanroom and purity standards

Importance of Fluoropolymer (HALAR/ETFE/PFA/FEP) Coatings in the Semiconductor Industry

The semiconductor industry operates in an environment that demands extremely high standards of safety, purity, and reliability. Manufacturing facilities handle a wide range of hazardous chemicals, flammable gases, and corrosive substances during wafer fabrication and related processes. Because of these conditions, the materials used in exhaust systems, ducts, piping, tanks, and processing equipment must provide exceptional resistance to fire, corrosion, and contamination. Fluoropolymer coatings have emerged as a critical solution to meet these stringent requirements and ensure safe, uninterrupted plant operations.

Role of Duct Systems in Semiconductor Industry

Semiconductor fabrication plants use extensive exhaust duct systems to remove hazardous gases generated during manufacturing. These gases are often flammable, corrosive, or reactive. If not handled properly, they can lead to severe industrial accidents. Historically, several incidents have demonstrated the risks associated with conventional duct materials.

For example, explosions have occurred due to reactions between accumulated deposits and moisture, accidental release of hydrogen into exhaust ducts, ignition of silicon compound residues caused by static electricity during maintenance, and corrosion-induced defects that allowed flammable gases to spread. Such incidents can result in fire propagation through the duct network, causing significant damage and plant shutdowns.

Because exhaust ducts interconnect various areas of the plant, a localized fire can quickly spread throughout the facility. This makes the selection of flame-resistant and corrosion-resistant materials essential for safe semiconductor operations.

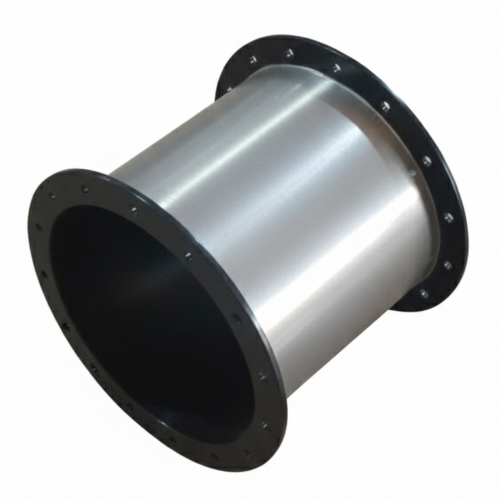

Need for Fluoropolymer Coatings in Ducts

To address these safety challenges, fluoropolymer coatings are widely used in semiconductor duct systems. These coatings provide two primary protective properties:

- Flame Resistance – The coating must resist ignition and prevent flame propagation even when exposed to flammable gases.

- Corrosion Resistance – It must withstand aggressive chemical environments and prevent degradation of duct materials.

Fluoropolymer coatings such as Halar (ECTFE), FEP, ETFE, PFA,PVDF and PTFE offer excellent resistance to both heat and chemicals. Their non-reactive nature reduces the risk of corrosion-related failures and helps maintain the integrity of exhaust systems over long operational periods.

Additionally, these coatings can reduce insurance risk and costs because they meet stringent fire safety standards recognized globally.

Importance of FM Approvals and Standards

FM Global, a major international insurance organization, has established strict combustion and safety standards for materials used in industrial facilities. In semiconductor plants, FM-approved products are considered the standard specification for exhaust duct systems

One of the most critical standards is FM 4922, which applies to “Duct Systems, Fume and Smoke Exhaust for Use in Cleanrooms.” This specification is among the most stringent because semiconductor manufacturing involves highly sensitive cleanroom environments and the handling of various flammable substances.

Factories designed with FM-certified materials are eligible for reduced fire insurance premiums, which provides a financial incentive in addition to improved safety. As a result, fluoropolymer-coated ducts have become widely adopted across global semiconductor facilities.

Applications of Fluoropolymer Coatings in Semiconductor Manufacturing

Fluoropolymer materials are not limited to exhaust ducts. They are extensively used across multiple components in semiconductor plants due to their chemical inertness and purity. Common applications include:

- Chemical piping and flexible tubing

- Valves and seals

- Detoxification equipment

- Chemical storage tanks

- Metal bottle linings

- Heat exchangers

- Exhaust ducts and ventilation systems

For instance ETFE, PFA coatings are used in chemical piping and tanks, while FEP and ETFE, Halar coatings are commonly applied to ducts and piping systems. These materials help prevent contamination, resist aggressive chemicals such as hydrofluoric acid, and maintain cleanroom standards.

In many applications, coatings also provide non-stick and mold-release properties, which reduce material build-up and improve maintenance efficiency.

Performance Advantages of Fluoropolymer Coatings

Fluoropolymer coatings offer several technical advantages that make them suitable for semiconductor environments:

1. Superior Chemical Resistance

They can withstand highly corrosive substances such as sulfuric acid, hydrofluoric acid, and organic chlorides commonly used in etching and cleaning processes.

2. Flame Retardancy

FM-approved fluoropolymer coatings resist ignition and help prevent the spread of fire through duct systems.

3. High Purity and Cleanroom Compatibility

These materials maintain low contamination levels, which is critical for semiconductor wafer fabrication where even microscopic impurities can affect product yield.

4. Thermal and Mechanical Stability

Fluoropolymers possess high melting points and maintain structural integrity under elevated temperatures and harsh operating conditions.

5. Non-Stick and Release Properties

Their low surface energy reduces adhesion of chemical residues, improving equipment lifespan and reducing maintenance frequency.